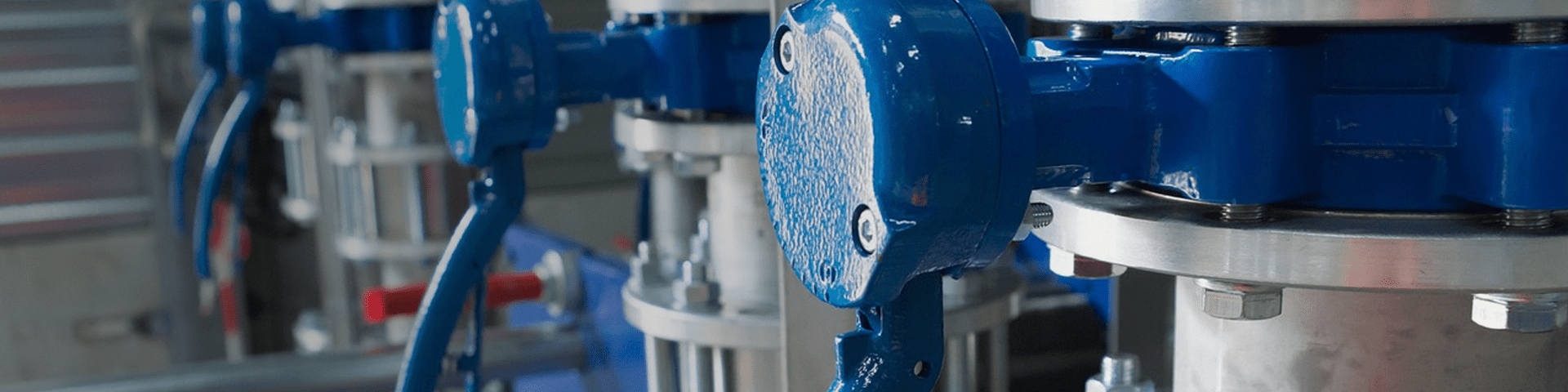

Ball valves are a critical component in various industrial and residential systems, controlling the flow of liquids and gases with reliability and precision. However, like any mechanical device, they require regular maintenance to ensure their longevity and optimal performance. In this blog post, we’ll explore some expert advice on maintaining and troubleshooting ball valves, with insights from leading ball valve manufacturers.

Before diving into maintenance, it’s essential to understand what a ball valve is and how it works. A ball valve consists of a spherical disc, the ball, which has a hole through its center. The ball’s position (in line with or perpendicular to the flow) controls the passage of fluid. This simple yet effective design is why many ball valve manufacturers are at the forefront of valve technology.

Visual Inspection: Regularly inspect the valve for signs of wear, corrosion, or damage. Look for leaks, which could indicate a compromised seal.

Operational Testing: Open and close the valve to ensure it operates smoothly. Any stiffness or irregularity could signal an issue.

Cleaning: Keep the valve clean from debris and buildup, which can affect its operation. Follow the cleaning guidelines provided by your ball valve manufacturer.

Lubrication: Apply appropriate lubricants to the valve’s moving parts, as recommended by the manufacturer, to prevent friction and wear.

Leaks: If you notice a leak, check the seals and gaskets. Over time, these can degrade and may need replacement.

Stiff Operation: Difficulty in operating the valve handle might be due to lack of lubrication or internal blockages. Consult with your ball valve supplier for the best course of action.

Unusual Noises: Any strange sounds during operation could indicate a problem. It’s best to shut down the system and inspect the valve.

Pressure Drops: A sudden drop in pressure might mean a partially closed valve or a blockage. Ensure the valve is fully open and clear of obstructions.

If troubleshooting doesn’t resolve the issue, it’s time to contact a ball valve manufacturer. They can provide expert advice, replacement parts, or suggest a new valve if necessary. Remember, choosing a reputable manufacturer is crucial, as they stand behind the quality of their products and support.

Proper maintenance and timely troubleshooting of ball valves can prevent system failures and extend the life of the valve. By following these tips and working closely with your ball valve manufacturer, you can ensure that your valves remain in top condition, providing efficient and reliable service for years to come.