In modern industrial production, valves are very common industrial components, especially in fluid systems. Due to various factors such as environment, safety, operation, and technology, a large number of valves are needed. Among them, swing check valves are widely used in fluid systems to control the flow direction and ensure the safety and reliability of the system. This article will focus on the advantages of swing check valves in fluid systems and explain how they work to control the flow direction.

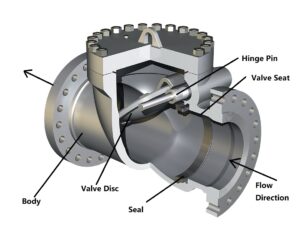

To understand the application of swing check valves in fluid systems, we first need to know what a swing check valve is. From its name, we can guess that it is a valve designed to prevent fluid from flowing backward, and it has a swinging motion. That’s correct—swing check valves control the flow direction by using a swinging disc inside the valve. When the fluid flows in the intended direction, it passes through easily. However, if the fluid tries to flow in the opposite direction, the disc, which is attached to a hinge, swings shut and blocks the reverse flow. This feature makes swing check valves widely used in fluid systems.

The working principle of a swing check valve is quite simple. By looking at the diagram, we can clearly understand its mechanism. The valve mainly consists of a valve body, hinge pin, disc, seat, and sealing parts. When the fluid flows in the designed direction, it pushes the disc open, allowing smooth flow. However, if the fluid tries to flow in the opposite direction, the disc closes against the seat and sealing parts, forming a tight seal that blocks the reverse flow. In simple terms, a swing check valve works like a one-way road where only traffic in the correct direction is allowed. The combination of the disc, seat, and seal acts as a gate that opens for the right direction and immediately closes for reverse flow.

Why choose a swing check valve over other types of check valves? There are certain advantages that swing check valves offer compared to other valves. Here are some key benefits:

Precise Control: The combination of the hinge pin, disc, and sealing parts provides excellent sealing performance, allowing more precise control of fluid flow direction and preventing backflow more effectively than other valves.

Low Noise: Noise pollution is a common issue in industrial production. While it’s hard to eliminate noise entirely, we can reduce it at various stages. One of the advantages of a swing check valve is its low operational noise. Its streamlined design and freely swinging disc help reduce the noise caused by fluid impact during operation.

Quick Response: Thanks to its streamlined design and the automatic swinging motion of the disc, the valve responds quickly to fluid flow, effectively reacting to changes in fluid movement.

Reduces Water Hammer Effect: In fluid systems, sudden changes in flow speed can cause a water hammer effect. The swing check valve’s design helps slow down fluid flow, reducing the risk of damage to pipes or valves caused by water hammer.

Durability: Swing check valves are typically made from high-strength materials like cast steel, stainless steel, or special alloys. These materials are robust, wear-resistant, corrosion-resistant, and suitable for harsh environments, ensuring long-term durability.

Easy Maintenance: Fluid systems are often complex and difficult to inspect or repair due to long and intricate piping. However, swing check valves have a simple structure, making them relatively easy to maintain and helping reduce overall operating costs of the system.

Swing check valves are found everywhere in piping systems and have a wide range of applications. Their use cases include, but are not limited to, the following:

Water Supply Pipelines: In water supply systems, swing check valves effectively prevent water from flowing backward, protecting water quality and ensuring cleanliness and safety.

Sewage Pipelines: In sewage treatment plants, these valves help prevent treated water from mixing with untreated water, maintaining the correct flow direction and preventing contamination of clean water.

Petrochemical Industry: In the oil and chemical industries, strict separation of liquids is required. Swing check valves effectively prevent cross-contamination between different products.

HVAC Systems: Swing check valves are used to prevent the backflow of hot or cold water, protecting equipment from damage caused by reverse flow.

In conclusion, swing check valves play a crucial role in fluid systems and are an essential component. They not only ensure unidirectional fluid flow and improve system efficiency but also reduce water hammer effects, enhancing the overall safety and stability of the fluid system while protecting equipment and components. With their streamlined design, simple yet effective sealing mechanism, and strong durability, swing check valves provide reliable, efficient fluid transmission and significantly reduce operational and maintenance costs. This is why they hold such great value in fluid systems.