Swing check valves have become an indispensable choice in many industries due to their simple and effective design, while ensuring reliable performance and minimal maintenance requirements. Whether you are in water systems, oil and gas pipelines or industrial manufacturing, you cannot do without swing check valves. How to choose a suitable supplier among many swing check valve manufacturers has always been a headache. This blog will introduce you to several leading swing check valve manufacturers in the USA.

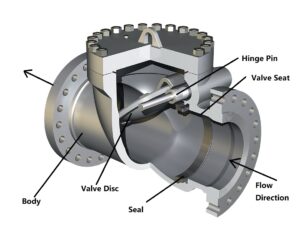

If you want to choose a suitable swing check valve manufacturer, you must first understand what a swing check valve is. Swing check valves are one-way valves that use a hinged valve disc. When the fluid flows forward, the valve disc opens, and when it flows in the reverse direction, the valve disc closes to prevent backflow. Therefore, a swing check valve can only allow the fluid to flow freely in one direction. This is the biggest feature of a swing check valve.

CNLD

CNLD Valves, a leading swing check valve manufacturer, is a subsidiary of ODK Valve Group and is well-known for its high-quality swing check valves that meet the needs of demanding industrial applications. With advanced manufacturing technology and strict quality control, CNLD stands out in the valve industry.

Precision Engineering: Their swing type check valves are made of stainless steel, providing excellent durability and reliability, and are easy to maintain and reduce costs.

Wide Range: CNLD Valves’ swing check valves have a wide range of raw materials and a wider range of applications, including cast steel, stainless steel, special alloy, CI, DI etc. Different types of raw materials, Size Range from 2″~36″, from standard sizes to custom solutions, CNLD has covered all your needs.

Compliance: Their products comply with BS1868 standards and have passed international standards such as API6D/CE/ISO9001/ISO14001 certification.

Application: CNLD Valves’ swing check valves are widely used in refineries, water treatment plants and chemical processing facilities, covering a wide range of fields and applications.

Kennedy Valve has been synonymous with valves in the valve industry and has been a benchmark for valves for more than a century. They specialize in providing powerful and effective valve check swing for municipal and industrial applications.

Cast iron and ductile iron options: Durable materials for longevity.

Ease of maintenance: Their designs are user-friendly, reducing downtime.

American-made: High-quality valves proudly manufactured in the USA.

Kennedy’s products are a favourite for water distribution and wastewater management systems, thanks to their proven performance and cost-effectiveness.And their valves meet the AWWA standards, and are suitable for projects with high durability and high reliability requirements.

If you want diversity, then Val-MATIC is a manufacturer that needs to be considered. Their extensive product lines include a rotary stop valve, a plug valve and an air swing valve. All these valves are tailor -made for specific applications.

Innovative design: Its spin -off -back valve has a strong structure and a large circulation area. It can effectively use the application of various pumping systems and buffer the design, which is conducive to quiet operation.

Customized options: Val-MATIC provides a solution tailor-made based on unique operating needs.

Environmental focus: The valve is designed for energy efficiency, which can effectively save pumping costs.

Val-MATIC’s spin-type stop valve is used for municipal water supply systems, irrigation and HVAC systems.

DeZURIK is synonymous with performance and reliability. Their APCO swing check valves are designed for challenging environments and provide superior sealing and flow control. They are widely used in water treatment, water distribution, industrial water, and wastewater services.

Corrosion-resistant materials: For harsh chemical and water environments.

High-pressure capabilities: For demanding applications.

Low-maintenance design: Designed for minimal maintenance.

DeZURIK serves industries such as pulp and paper, food processing, and power generation where reliability is non-negotiable.

Mueller swing check valves are designed specifically for water and wastewater applications. With a history dating back to 1857, they’ve earned a reputation for quality and innovation.

Lightweight designs: Rubber disc facing,easier to handle and install.

Elastic seat: Ensures a tight seal and long service life.

Wide distribution network: Readily available throughout the USA.

From municipal water systems to irrigation networks, Mueller is a trusted choice for engineers and contractors alike.

Flomatic Corporation specialises in lightweight and durable swing check valves, available with either metal-to-metal or resilient seats, ideal for applications that require ease of operation and installation.

Compact and lightweight design: Ideal for installations where space is limited.

High flow: Your valves maintain efficiency even under the most demanding conditions.

Versatile applications: They can be used in everything from potable water systems to HVAC.

Flomatic swing check valves are commonly used in residential and commercial plumbing systems where efficiency and reliability are paramount.

Milwaukee Valve offers affordable options without sacrificing quality. Their swing check valves provide reliable performance for budget-conscious projects.

Cost-effective: Excellent performance at a competitive price.

Durable construction: Designed to withstand frequent use.

Prompt delivery: A reliable supply chain ensures timely delivery.

Milwaukee Valve swing check valves are commonly used in commercial construction and light industrial applications.

Q1: What is the difference between a swing check valve and a spring check valve?

A:Both swing check valves and spring check valves are check valves. The spring check valve relies mainly on spring force to assist the opening and closing of the valve disc. Due to the auxiliary effect of the spring, the sealing performance is better and due to the rapid closing of the spring, the water hammer phenomenon can be reduced. It is suitable for systems with large changes in fluid flow. The swing check valve relies on the hinged disc to open and close the disc by the fluid pressure difference to achieve fluid shut-off, and is suitable for situations where the fluid flows continuously.

Q2:Can swing check valves be used for air systems?

A:The swing check valve can be used in air systems, but in some air systems it can cause an air hammer effect when the pressure changes instantaneously, and it is easily affected by the air flow rate and cannot start or close properly.

Q3:What are common problems with swing check valves?

Water hammer: This can happen if the valve closes too quickly.

Air hammer: In air systems, air hammer can occur due to instantaneous pressure changes.

Wear: As swing check valves are used over time, the hinges or valve seats can wear and age.

Debris build-up: In some piping systems, debris in the medium can cause blockages that prevent normal operation.

Swing check valves are essential in ensuring one-way flow in pipelines and preventing backflow. Whether in municipal water supply systems, industrial pipelines, or petrochemical pipelines, choosing the right manufacturer greatly ensures the working performance of swing check valves. Companies such as CNLD, Kennedy Valve, Val-Matic, DeZURIK, Mueller, Flomatic Corporation, and Milwaukee Valve provide first-class swing check valve solutions to meet your needs.

If you are still learning about swing check valves and want to choose an advantageous manufacturer, please check out this blog to help you understand the top swing check valve manufacturers in the United States. Remember, the right valve not only ensures efficiency, but also prolongs the life of the system.