V-port ball valves are a key component in precision flow control applications, especially in systems that require accurate modulation and throttling. As a type of v port valve, they are engineered with a machined V-shaped notch on the ball or seat, enabling precise flow regulation and delivering linear or equal-percentage flow characteristics. Unlike traditional on/off port valves, a v port configuration provides enhanced control, making it ideal for process industries where tight shut-off and reliable flow management are essential.

This article explores the structure, working principles, advantages, and wide-ranging industrial applications of V-port ball valves in depth.

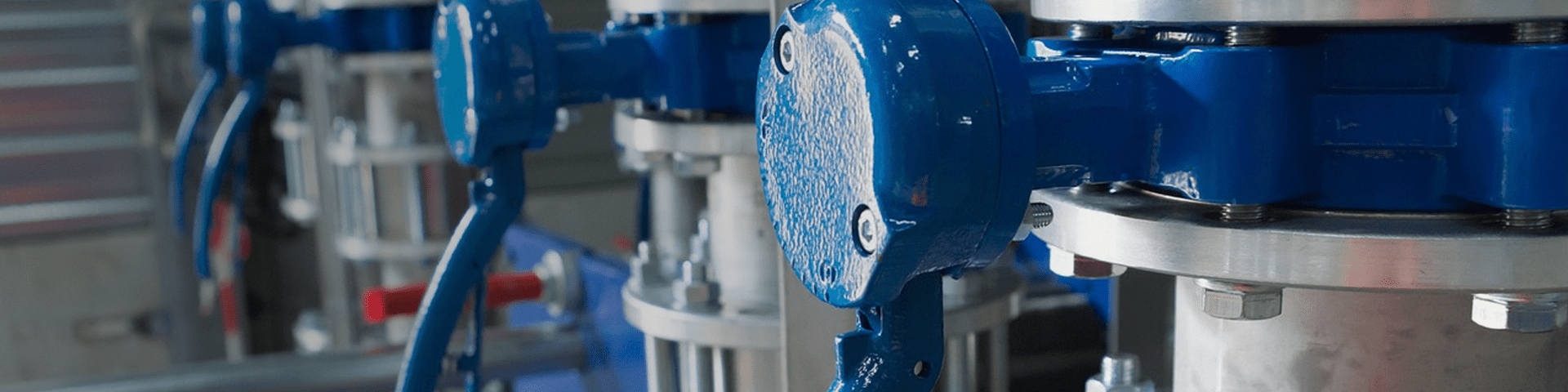

A V-port ball valve is a rotary control valve designed for throttling flow with high precision. The defining characteristic of this valve is its V-shaped port—typically machined into the ball itself or the seat—which enables variable flow control based on the valve’s opening angle.

Valve Body Material Availability:

| Part | Material |

| Body | WCB, CF8M, Duplex SS, Alloy 20 |

| Ball | 316SS, Tungsten Carbide Coated |

| Seat | PTFE, RTFE, Metal (Stellite) |

| Stem | 17-4PH, SS420, Inconel |

As the V-notched ball rotates via quarter-turn motion, the increasing open area between the ball and seat allows for incremental flow control. The notch geometry determines the flow characteristic:

V-ball valves are not pressure-balanced, so actuator sizing should consider differential pressure and required Cv (flow coefficient). Typical actuation options include spring-return pneumatic actuators or modulating electric actuators.

These precision ball valves are engineered for consistent throttling, and their low torque operation supports the use of compact actuators, reducing total system cost.

| Parameter | V-Port Ball Valve | Full Port Ball Valve |

| Flow Control | Precise modulation | On/Off only |

| Internal Design | V-shaped port or segment | Full sphere |

| Cv Value (Flow Capacity) | Lower than full port | Higher Cv |

| Torque Requirement | Low torque valve | Higher torque required |

| Application | Modulating/Control service | Isolation only |

V-port valves are engineered for precision flow capacity management, while full port ball valves are preferred for unrestricted flow and minimal pressure drop in on/off applications.

Thanks to their excellent throttling capabilities, linear or equal-percentage flow characteristics, and robust rotary design, V-port ball valves are widely adopted in industries that demand precise and repeatable flow control.

Unlike conventional full-port valves used for isolation, V-ball valves are engineered specifically for modulating services—particularly under varying pressure and flow conditions. Below are the most common and critical application sectors:

In chemical process systems, accurate control of corrosive fluids, slurry, or hazardous chemicals is critical to safety and efficiency. V-port valves, especially those made from PTFE-lined stainless steel or Alloy 20, are widely used for:

In upstream, midstream, and downstream applications, V-notch control valves offer enhanced reliability for wellhead control, separator level regulation, and chemical injection skids.

Typical applications include:

In power plants, particularly combined cycle and cogeneration units, precise steam and water control is vital. V-port valves replace bulkier globe valves in:

In sanitary and hygienic applications, stainless steel V-ball valves offer smooth throttling for clean liquids, syrups, and CO₂ injection.

Common uses include:

In pharmaceutical manufacturing, the requirements for repeatability, precise dosing, and FDA-compliant construction make V-port valves a preferred solution.

They are ideal for:

This sector involves abrasive and fibrous media, which necessitates metal-seated segmented ball valves for flow control in:

In wastewater and sludge systems, V-ball valves handle low solids, chemical dosing, and flow equalization processes with great control precision.

They are applied in:

The V-port ball valve provides a compact, efficient, and accurate flow control solution across a wide range of industrial applications. By selecting the appropriate notch angle, seat material, and actuation mode, engineers can precisely match valve performance to system requirements.

For engineered systems that require both control accuracy and durability under demanding conditions, a properly specified V-port ball valve is an ideal choice. Whether you’re sourcing from a trusted V-port ball valve supplier in China or integrating it into your HVAC, food processing, or chemical flow systems, the design versatility and flow efficiency of this control valve make it a proven performer. What is a V-port ball valve and its applications?