A pressure seal swing check valve is a type of check valve, also known as a one-way valve, used in pipelines. It is designed to allow the medium to flow in only one direction, preventing reverse flow. As the name suggests, a pressure seal swing check valve uses pressure to seal and only allows one-way flow. Within its designed pressure range, the higher the pressure, the better the sealing performance. Based on the BS1868 standard, it is usually made from high-strength materials like cast steel, stainless steel, or special alloys. This type of check valve is commonly used in industries such as oil, chemicals, natural gas, and power generation.

Source:cnldvalves

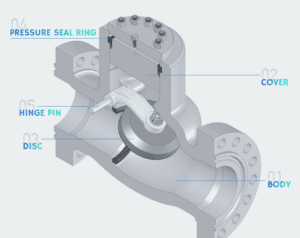

Let’s first look at the structure of a pressure seal swing check valve. As shown in the diagram, it consists of a body, cover, disc, pressure seal ring, and hinge pin. When the medium flows in the specified direction, it pushes the disc open, allowing the medium to pass through. The design of the hinge pin ensures that there is no obstruction when the medium pushes the disc, preventing any pressure drop. When the medium tries to flow back, the disc automatically closes due to gravity or pressure, blocking the reverse flow. This allows the valve to stop reverse flow without any external operation, protecting the equipment in the system.

By understanding the working principle of a pressure seal swing check valve, we can clearly see that it can be installed vertically. However, certain conditions must be met for vertical installation. Since the valve controls the flow direction through the disc and hinge pin, the medium must flow from bottom to top during vertical installation. This ensures that the disc can open and close properly. If the installation direction or flow direction is incorrect, the valve may not fully close, leading to possible backflow.

Vertical installation puts more wear on the disc and hinge pin, so regular inspections and maintenance are necessary to ensure the valve maintains its excellent sealing performance.

Space-saving: Pressure seal swing check valves are relatively large and require significant space for installation. In cases where the pipeline layout has limited space, vertical installation can save a lot of room, making it especially suitable for complex high-pressure systems.

Strong adaptability: Whether installed horizontally or vertically, the pressure seal swing check valve offers multiple installation options. This allows it to fit into different pipeline layouts, avoiding limitations due to vertical installation restrictions and improving overall system efficiency.

Flow direction limitation: Vertical installation is only suitable for media flowing from bottom to top. If the flow is from top to bottom, the valve may not close properly, compromising the system’s overall sealing.

Disc wear: The swinging motion of the disc can be affected during long-term vertical use, especially with frequent opening and closing. This may lead to accelerated wear, causing sealing issues.

1.Ensure the flow direction: For vertical installation, the medium must flow from bottom to top. If not, the valve may not function properly, which could affect the overall sealing of the system.

2.Pipe cleaning: Before installation, the pipeline should be cleaned to remove any debris or particles. These particles can not only affect the valve’s sealing but also cause significant wear on the sealing components.

3.Correct valve selection: Always follow the product manual for installation. Not all pressure seal swing check valves are suitable for vertical installation. It’s crucial to check beforehand and ensure the selected model supports vertical installation.

4.Regular maintenance: After vertical installation, the valve should be inspected and maintained regularly to ensure optimal performance. In high-pressure systems, long-term use may accelerate wear on the disc and sealing surfaces, so regular maintenance helps extend the valve’s service life.

After understanding the characteristics of the pressure seal swing check valve, it is clear that this type of valve can be installed vertically. Vertical installation can improve the overall efficiency of the pipeline system and save space. However, certain requirements must be followed during the installation process, ensuring it is done according to the valve’s structural features. Additionally, regular maintenance and upkeep are essential to ensure the valve performs at its best over time.

Q1: Can all pressure seal swing check valves be installed vertically?

A: No, only certain models are suitable for vertical installation. You should select the appropriate product based on system requirements before installation.

Q2: Will vertical installation affect the flow rate of the medium in the system?

A: Vertical installation has a minimal impact on the flow rate, but it’s still important to evaluate the system’s design and valve specifications to ensure proper flow and pressure compatibility.

Q3: What is the pressure rating of a pressure seal swing check valve?

A: The pressure rating of a pressure seal swing check valve is defined by the American Society of Mechanical Engineers (ASME) standards. Common pressure ratings include 150, 300, 600, 900, 1500, and 2500, which refer to the maximum working pressure the valve can withstand at a specified temperature.

Q4: What is the edition of BS1868?

A: BS1868 is a standard related to steel check valves for use in the petroleum, petrochemical, and related industries. It covers various types of check valves and specifies design, materials, pressure ratings, and dimensions for these valves.